by Christine Shores | May 24, 2019 | Blog

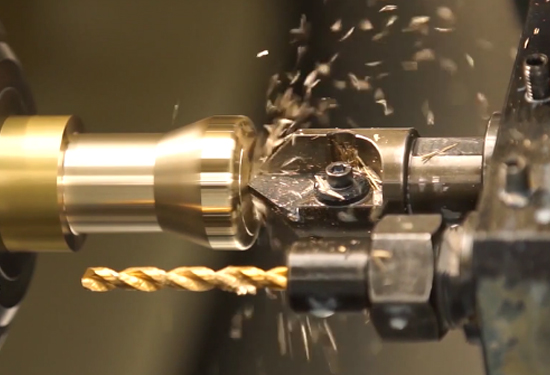

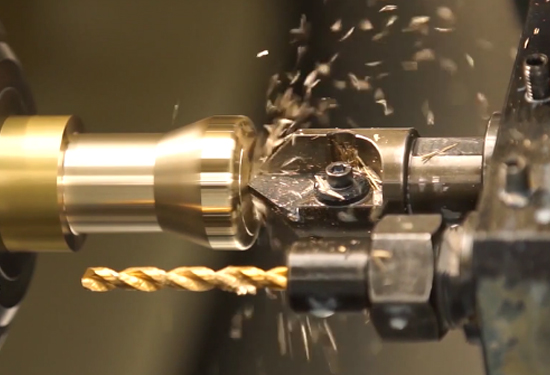

Mechining 4 Best practices for machining ECO BRASS® and ECO BRONZE Wieland Chase is proud to offer technical support for our customers who are interested in machining ECO BRASS® C69300 and ECO BRONZE® C87850. These alloys are lead-free but machinable and corrosion...

by Christine Shores | Jan 10, 2019 | Blog

Recycling Brass Brass can be recycled indefinitely, therefore, it is very valuable to the scrap industry. Wieland Chase’ scrap metal recycling program is vital to producing globally competitive brass products and we welcome our customer’s partnership in understanding...

by Christine Shores | May 31, 2018 | Blog

As one of the world’s leading brass companies, Chase holds its brass manufacturing tolerances to the tightest standard in the industry when it comes to high quality brass. We use state-of-the-art chemical analysis equipment and detailed testing procedures to insure...

by Christine Shores | Dec 7, 2017 | Blog

The results are in! A scientific study commissioned by the California Metals Coalition has proven ECO BRASS® to be a superior choice for drinking water applications compared to other tested brass alloys. [1]The three key ECO BRASS® characteristics – performance,...

by Christine Shores | Sep 21, 2017 | Blog

To the unknowing eye, brass is brass. But we in the industry know there are many variables in brass alloys which are used in wide ranging applications. In order to effectively select the correct brass for a given application, critical attributes of the final product...

by Christine Shores | Aug 3, 2017 | Blog

Wieland Chase is leading the way in the supply of forged brass components utilizing Brass in their Wieland Forgeworks product line. Our economic and flexible forging capability allows for additional material savings by utilizing up to three cores per part. This...