NSF/ANSI/CAN 61

Keeping You in Compliance

On January 1, 2024 the NSF/ANSI/CAN 61 Section 9 Lead Leachate Standard will become mandatory

Be ready with our lead-free* and low-lead brass solutions

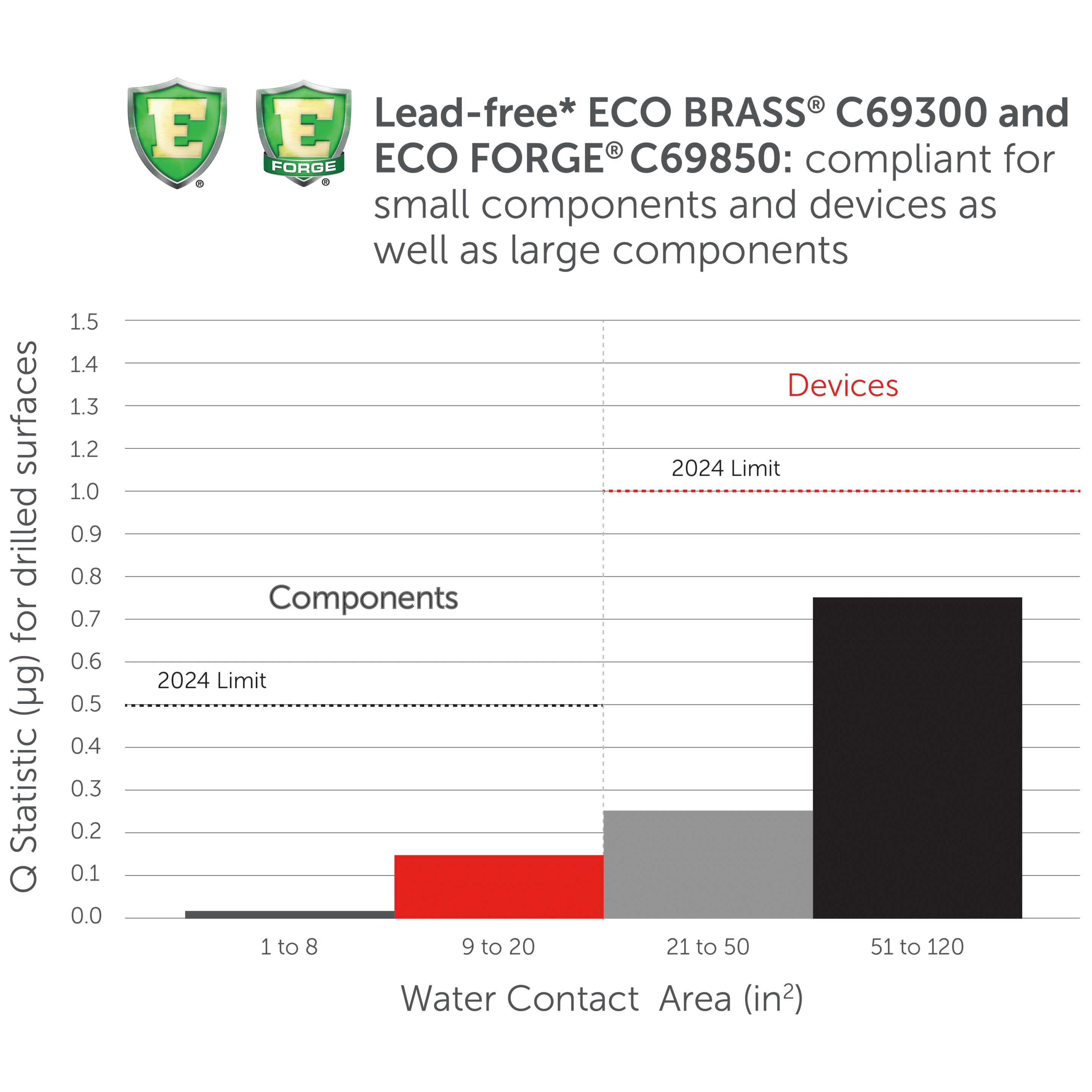

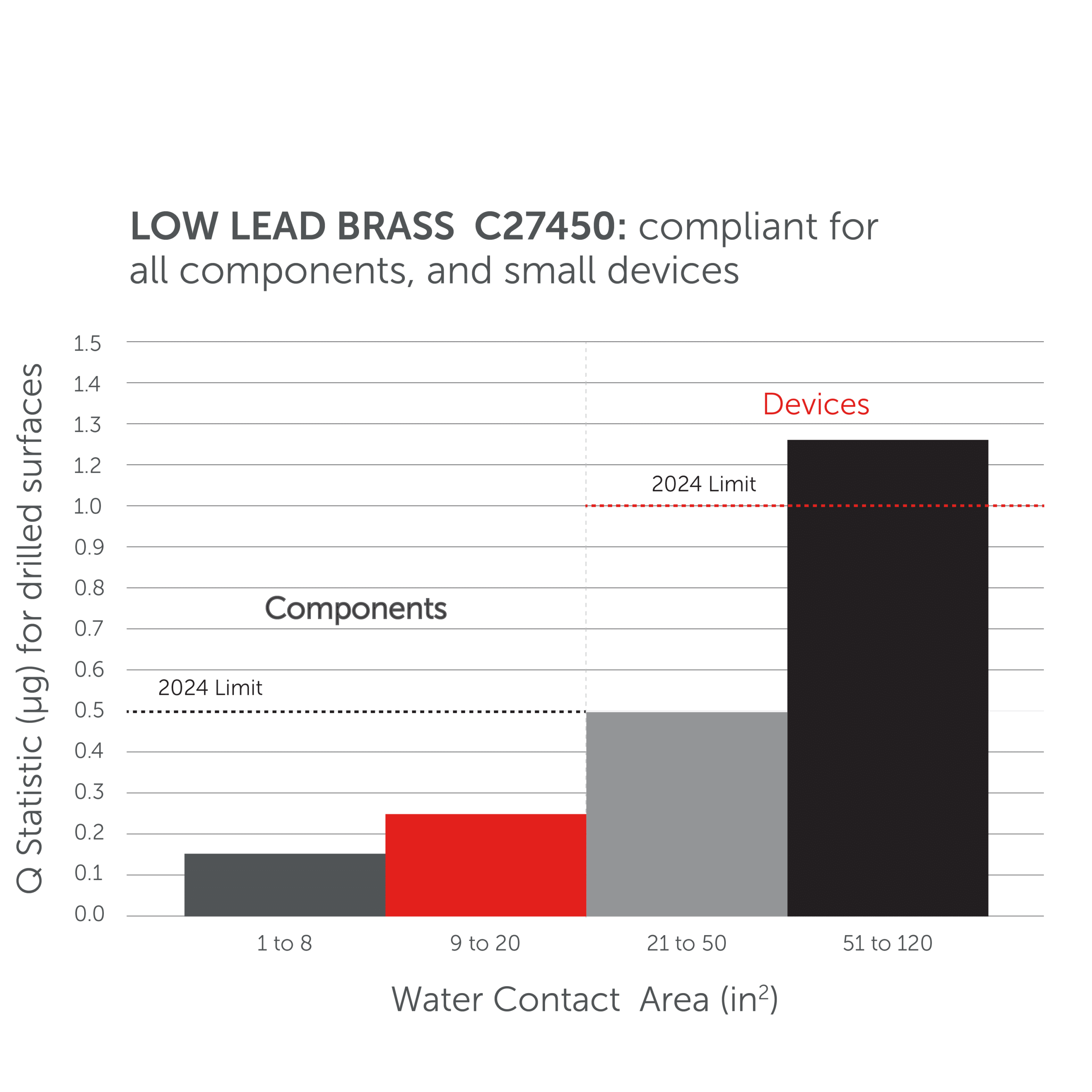

We have excellent American-made brass solutions that will ensure you comply with the current and coming standards. Our three brass options, ECO FORGE®, ECO BRASS® and Low Lead Brass, have been successfully used for part production and are the ideal fit to keep your components compliant as we move toward 2024. Select the brass alloy that works best for the products you are manufacturing. These three options provide sound solutions to continue operating in compliance withNSF/ANSI/CAN 61, Section 9 lead leachate standard.

NSF/ANSI/CAN 61 Section 9 Requirements:

- Mandatory January 1, 2024

- Reduced from 5 to 1 µg for endpoint devices (e.g. faucets)

- Reduced from 5 to 0.5 µg for components (e.g. valves)

Average “Q” values for drilled, water contact surfaces, Extrapolated to 8,20,50 and 120 in2

1 to 8 (in2)

Small Components

Fittings, shut-off valves, valve cartridges,

center body tees, aerator housings

9 to 20 (in2)

Large Components

Faucet bodies & Faucet spouts

21 to 50 (in2)

Small Devices

Bathroom faucets

51 to 120 (in2)

Large Devices

Kitchen faucets, drinking fountain bubblers

Alloy Properties and Machinability

| Property | C69300 ECO BRASS®1 | C69850 ECO FORGE®2 | C27450 LOW LEAD®1 |

|---|---|---|---|

| Tensile Strength (ksi) | 90 | 77 | 63 |

| Yield Strength (ksi) | 48 | 55 | 40 |

| Elongation (%) | 35 | 22 | 28 |

| Mid-Radius Hardness (Rb) | 88 | 87 | 74 |

| Dezinc. Depth (µm)3 | 0 | 40 | 400 |

| Machinability (vs C360)4 | 85 | 82 | 70 |

2Average of maximum dezincification depth values from Corrosion Testing Lab, Newark DE

3Based on production experience and independent lab testing machinability rated at 100% for single point machining

Nominal Alloy Composition (with ASTM Ranges)

| Alloy | C69300 ECO BRASS® | C69850 ECO FORGE® | C27450 LOW LEAD® |

|---|---|---|---|

| Copper (%) Nominal ASTM |

75.3 73-77 |

68.4 67.5-69 |

61.6 60-65 |

| Lead (%) Nominal ASTM |

0.05 0.09 max |

0.05 0.09 max |

0.18 0.25 max |

| Silicon (%) Nominal ASTM |

2.9 2.7-3.4 |

1.7 1.53-2.0 |

– |

| Phos. (%) Nominal ASTM |

0.1 0.04-0.15 |

0.09 0.04-0.15 |

– |

| Zinc (Approx. %) Nominal ASTM |

21.5 Remainder |

29.8 Remainder |

38 Remainder |

* This product complies with 0.25% weighted average lead content on wetted surfaces in accordance with Safe Drinking Water Act (SDWA) / Federal Public Law No. 111-380.

About Us

Wieland Chase is a leading brass manufacturer and supplier for brass alloys in North America. As of July 2019, Wieland Chase became part of the strong global Wieland Group with a continued commitment to safety, quality and customer service. More about the Wieland Group

Contact Us

Online Payment

14212 Selwyn Drive

Montpelier, OH 43543

p 419-485-3193

p 800-537-4291

f 419-485-5945

Copyright 2025 © Wieland.

All Rights Reserved.

ECO BRASS® is a registered trademark of Mitsubishi Materials Corporation. Used with permission.