Copper & Brass Alloys – RoHS Frequently Asked Questions

Understand Restriction of Hazardous Substances (RoHS) Specifics Related to Copper and Brass Alloys

Updated January 2022

What is RoHS?

RoHS stands for the Restriction of Hazardous Substances. The original RoHS, informally referred to as RoHS I, was implemented in the European Union in 2003 under EU Directive 2002/95/EC. It set limit values for lead, cadmium, and several other chemicals in specified types of electrical and electronic equipment, including a lead maximum of 0.1%.

When did RoHS take effect?

The RoHS restrictions became effective with electrical and electronic equipment put on the market on and after July 1, 2006.

Which companies are affected by RoHS?

Any business that sells electrical and electronic equipment to EU countries, including resellers, distributors and assemblers, that utilize materials restricted by RoHS.

Are copper alloys that contain lead (Pb) affected by RoHS?

As noted in Annex III, Exemption 6(c) was granted for lead in copper and brass alloys, allowing up to 4% lead (Pb) by weight. Other exemptions were also included in RoHS I where no satisfactory alternatives were available. The directive required that exemptions be reviewed at least every four years with the aim of deleting the exemption if their elimination or substitution is technically or scientifically possible, provided that the negative environmental, health and/or consumer safety impacts caused by the substitution do not outweigh the benefits.

What about RoHS II?

In 2008, the EU launched a revision of RoHS. This process was completed in 2011 when Directive 2011/65/EU, informally known as RoHS II, was adopted. RoHS II became effective in January 2013, replacing RoHS I. The exemption process in RoHS II was also amended. The four-year review process of RoHS I, which was to be automatically conducted by the government, was abolished. Instead, under RoHS II, the burden was placed on parties (i.e. industry) wishing to maintain an exemption to file an application for renewal 18 months before expiry.

What about RoHS III?

informally known as RoHS III, came into force on July 22, 2019. Medical devices, monitoring and control tools received an additional two years to comply. Notably, RoHS III added four new restricted substances which are different types of phthalates used in plasticizers. These chemicals are not present in copper alloy semi-fabricated products such as brass rod. A new “catch-all” product category was also added to cover electrical/electronic equipment not specified in other categories.

What is the current status of Exemption 6(c)?

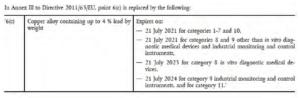

Copper and brass alloys containing up to 4% lead (Pb) by weight remain compliant under the latest revision of the directive (RoHS III)as summarized in the amendment to Annex III published inMay 2018 and shown in the excerpt below. The expiry date for the current renewal cycle is July 21, 2021, 2023 and 2024depending on the product category. The full legislation and amendments are available here: https://bit.ly/2Uc8xlH.

Did Exemption 6(c) expire on July 21, 2021?

No. An application to renew Exemption 6(c) was successfully filed by a large industry working group in January 2020 before the submission deadline. The application was endorsed by 48 trade associations demonstrating strong support from industry. As stated in the application, despite massive ongoing research on lead-free alternatives, it is still mostly not possible to substitute leaded copper alloys. As such, an extension for Exemption 6(c) was requested for the maximum permissible validity period.

When will the Commission decide on the renewal application?

A decision was expected by January 2021. However, the review experienced significant delays which is consistent with previous

cycles. In January 2022, the technical consultant assigned by the EU Commission published its recommendation to renew Exemption 6(c) with no changes through July 21, 2026. The Commission must now deliberate and decide if the recommendation should be accepted or modified. As such, the final decision published in the Official EU Journal may not arrive until late 2022. It is very important to note that Exemption 6(c) will remain valid during the extended deliberation period per Article 5, and manufacturers can continue using copper alloys with up to 4% lead after July 21, 2021:

“The Commission shall decide on an application for renewal of an exemption no later than 6 months before the expiry date of the existing exemption unless specific circumstances justify other deadlines. The existing exemption shall remain valid until a decision on the renewal application is taken by the Commission.”

Content created by the Copper Develpment Assossiation Inc. Download full pdf here.

About Us

Wieland Chase is a leading brass manufacturer and supplier for brass alloys in North America. As of July 2019, Wieland Chase became part of the strong global Wieland Group with a continued commitment to safety, quality and customer service. More about the Wieland Group

Contact Us

Online Payment

14212 Selwyn Drive

Montpelier, OH 43543

p 419-485-3193

p 800-537-4291

f 419-485-5945

Copyright 2023 © Wieland.

All Rights Reserved.

Privacy Policy

Terms and Conditions