About Us

Keeping You in Compliance

Our ECO alloy products meet all standards and compliance for NSF/ANSI/CAN 61, Section 9 lead leachate standard requirements, which are mandatory for certification in 2024. That’s why our brass options of lead-free ECO BRASS®, lead-free ECO BRONZE® and Low Lead Brass, have been successfully used in the production of parts for a wide range of compliance and high-strength parts and components when the highest purity, made-in-USA brass products are needed.

As stricter requirements are mandated worldwide on materials that come into contact with drinking water, the appropriate selection of alloys for drinking water installations is extremely important. Copper alloys, like ECO BRASS and ECO BRONZE, have proven themselves, technically and hygienically, in potable and drinking water installations around the world and will continue to be the basis for clean drinking water in the future.

Lead-Free Alloys to Ensure Safe Drinking Water

ECO BRASS and ECO BRONZE are ideal for applications that call for lead-free brass plumbing products for drinking water system components, such as PEX fittings, brass fittings, bronze fittings, stop valves, faucets, and other plumbing parts. Wieland Chase ECO Solutions products are dezincification resistant and stress corrosion cracking (SCC) resistant.

Specifying Lead-free Brass and Bronze Alloys

Wieland Chase is your source for ECO solutions when you need to specify and stock lead-free alloys that meet the latest requirements to ensure that your brass products meet all current standards such as the Reduction in Lead Drinking Water Act and Safe Drinking Water Act (SDWA). Wieland Chase is committed to manufacturing alloys that meet or exceed public health and safety standards as established by federal regulation and the NSF.

Buyers and specifying engineers should be sure to indicate any compliance needs in your specs, for example, requiring that any product designed and manufactured for dispensing potable water meet NSF 61 and NSF 372 test standards via third-party testing and certification. Contact us to discuss your lead-free alloy needs.

As your source for the supply and distribution of lead-free, silicon brass rod and bar stock, we carry an extensive supply of ECO alloy products and can fill bulk orders for ECO BRASS and ECO BRONZE products. Wieland Chase ECO alloy brass profiles are available in hexagon, round, and other shaped brass rods and brass bars.

Regulations for Lead-Free Materials

The Safe Drinking Water Act governs the quality of drinking water, with the focus being on specific elements used in drinking water systems. Regulations for the lead content in components used in drinking water systems are governed by the Reduction of Lead in Drinking Water Act, which came into effect in all U.S. states as of January 2014.

The weighted average lead content in pipes, fittings, fixtures and other components used to convey or dispense drinking water must not exceed 0.25 %. In practice, this means the lead content of components used to convey or dispense drinking water is limited to a maximum of 0.25 %.

Lead Leachate Performance

CDA sponsored project for independent laboratory measurement of lead leachate

NSF/ANSI/CAN 61 leachate test for all ECO BRASS® and ECO BRONZE® products:

- F1807 Fittings tested for NSF/ANSI/CAN 61 Compliance resulted in lead leachate below the detection limit of 0.5 ppb.

- The ECO BRASS® and ECO BRONZE® family has a Day 3 Q value of 0.25 ppb.

Table 1: Lead (Pb) Composition Determined by ICPMS Following Digestion (mg/kg)

| C36000 | C69850 | C69300 | |

|---|---|---|---|

| Sample 1 | 26,300 | 354 | 658 |

| Sample 2 | 26,900 | 371 | 645 |

| Sample 3 | 26,500 | 355 | 682 |

| Average | 26,566.67 | 360.00 | 661.67 |

| Average (%) | 2.66% | 0.036% | 0.066% |

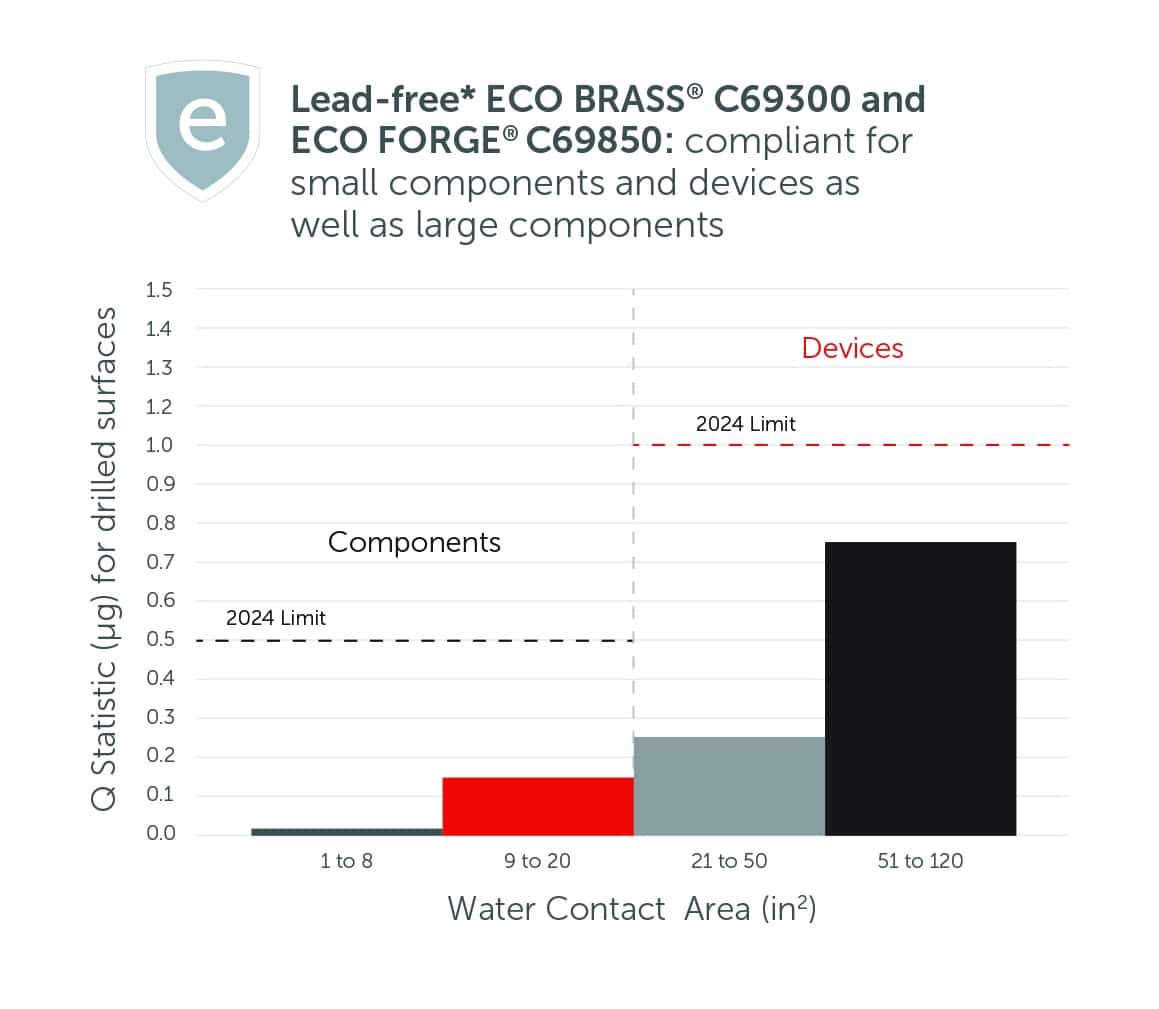

Table 2: Acceptance Criteria for Lead

| Current Q Value | Proposed Q Value | Proposed 3 Day Level (ug) | |

|---|---|---|---|

| Assembled Product | 5 | 1 | 3 |

| Component | 3 | 0.5 | 1 |

Table 3: Lead Q-statistic Values and Average Day 3 Lead Doses by Alloy Type

| Alloy | C36000 | C37700 | C69850 | C69300 |

|---|---|---|---|---|

| Q Statistic | 2.8 | 0.94 | 0.085 | 0.20 |

| Avg Day 3 Lead Dose (ug) | 7.5 | 4.1 | 0.25 | 0.48 |

Product Brochures

About Us

Wieland Chase is a leading brass manufacturer and supplier for brass alloys in North America. As of July 2019, Wieland Chase became part of the strong global Wieland Group with a continued commitment to safety, quality and customer service. More about the Wieland Group

Contact Us

Online Payment

14212 Selwyn Drive

Montpelier, OH 43543

p 419-485-3193

p 800-537-4291

f 419-485-5945

Copyright 2023 © Wieland.

All Rights Reserved.

Privacy Policy

Terms and Conditions